Innovations in Printed Circuit Board (PCB) materials have been driving significant advancements in the electronics industry, revolutionizing the way electronic devices are designed and manufactured. As the demand for smaller, faster, and more efficient electronic products continues to rise, the role of PCB materials in ensuring optimal performance and reliability has become increasingly crucial. In this article, we will explore the latest trends, challenges, and breakthrough innovations in PCB material technology, shedding light on what the future holds for this essential component of modern electronics.

Introduction to Printed Circuit Board Materials

If you’ve ever peeked inside your electronic gadgets, you’ve likely seen a maze of interconnected lines and components. These magic carpets of connectivity are made possible by printed circuit boards (PCBs) and the materials that bring them to life. So, buckle up as we dive into the world of PCB materials!

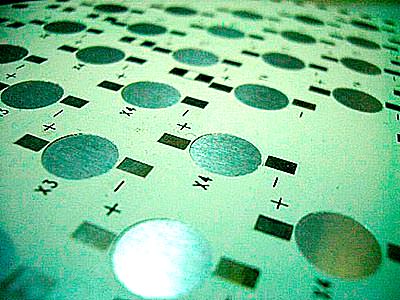

Overview of PCB Materials

PCB materials are like the unsung heroes of the electronics world, quietly supporting the intricate dance of electricity that powers our devices. From fiberglass substrates to copper traces, these materials form the backbone of modern electronics, allowing signals to flow and components to work together seamlessly.

Significance of PCB Materials in Electronics Industry

Without PCB materials, our smartphones would be dumb, our smart homes would be clueless, and our laptops would be lost. These materials play a crucial role in shaping the performance, reliability, and functionality of electronic devices, making them indispensable in today’s tech-driven world.

Current Trends and Challenges in PCB Materials

In the fast-paced world of electronics, staying ahead of the curve is key. Let’s take a closer look at the latest trends and hurdles facing PCB materials in an ever-evolving industry.

Industry Landscape of PCB Materials

The PCB materials landscape is akin to a bustling marketplace, with traditional players and innovative newcomers vying for attention. From rigid to flexible substrates, the variety of materials available reflects the diverse needs of electronic applications, driving competition and creativity in the market.

Challenges Faced by Traditional PCB Materials

While traditional PCB materials have served us well, they’re not immune to challenges. As devices become smaller, faster, and more complex, demands for higher performance and reliability push the limits of existing materials. From signal integrity issues to thermal management concerns, traditional materials are facing growing pains in a rapidly changing industry.

Emerging Innovations in PCB Material Technology

As the saying goes, “out with the old, in with the new.” Let’s explore the cutting-edge innovations reshaping the world of PCB materials and paving the way for the electronics of tomorrow.

Nanotechnology Applications in PCB Materials

Think small, really small. Nanotechnology is making big waves in PCB materials, offering enhanced conductivity, miniaturization, and performance. By harnessing the power of nanomaterials, PCBs are becoming lighter, faster, and more efficient than ever before.

Conductive Polymers and Flexible Substrates

Flexibility is the name of the game when it comes to the next generation of PCB materials. Conductive polymers and flexible substrates are bending the rules of traditional rigid boards, opening doors to new possibilities in design, form factor, and functionality. Say goodbye to clunky circuits and hello to sleek, adaptable solutions.

Impact of Advanced Materials on PCB Performance

The proof is in the performance pudding, and advanced PCB materials are serving up some tasty results. Let’s dig into how these materials are raising the bar for electronics in terms of conductivity, reliability, and overall awesomeness.

Enhanced Electrical Conductivity and Heat Dissipation

When it comes to electrical performance, every millimeter matters. Advanced PCB materials are boosting conductivity levels and improving heat dissipation, ensuring that your devices stay cool under pressure and deliver a constant stream of power without breaking a sweat.

Improvements in Durability and Reliability

Nobody likes a flaky circuit, especially when your favorite device goes on the fritz. With advanced materials, PCBs are becoming more durable, reliable, and resistant to environmental stressors. Whether it’s extreme temperatures or rough handling, these materials are built to last and keep your electronics running smoothly for the long haul.

Future Prospects and Development in PCB Material Industry

Get ready to buckle up, because the PCB material industry is on the fast track to innovation town! With advancements in technology and materials, the future of printed circuit boards is looking brighter than a supernova. From flexible PCBs to high-frequency materials, the possibilities are endless. Stay tuned as PCB-Togo Electronic, Inc. leads the charge in shaping the future landscape of PCB materials.

Strategic Partnerships for Material Advancements

In the world of PCB materials, collaboration is the name of the game. Strategic partnerships between material suppliers, manufacturers, and technology experts are driving groundbreaking advancements in PCB materials. By joining forces and sharing expertise, these partnerships are paving the way for new materials with enhanced performance, durability, and flexibility. PCB-Togo Electronic, Inc. is at the forefront of forging these alliances to push the boundaries of what’s possible in the PCB world.

Market Trends and Forecast in PCB Materials Sector

Curious about what’s hot and what’s not in the PCB materials sector? Look no further! Market trends indicate a growing demand for environmentally-friendly materials, high-speed, and high-frequency boards, as well as the rise of flexible and rigid-flex PCBs. With the increasing adoption of IoT devices, 5G technology, and electric vehicles, the demand for advanced PCB materials is set to skyrocket. PCB-Togo Electronic, Inc. is keeping a pulse on these trends to ensure they stay ahead of the curve and continue to deliver cutting-edge solutions to their customers.

In conclusion, the continuous evolution of PCB materials is poised to shape the future of electronics, offering enhanced functionality, performance, and sustainability. As researchers and industry experts push the boundaries of material science, we can expect to see even more groundbreaking innovations that will further transform the way electronic devices are designed and manufactured. Stay tuned for what’s next in the dynamic world of PCB materials, as the journey towards smarter and more efficient electronics continues to unfold.