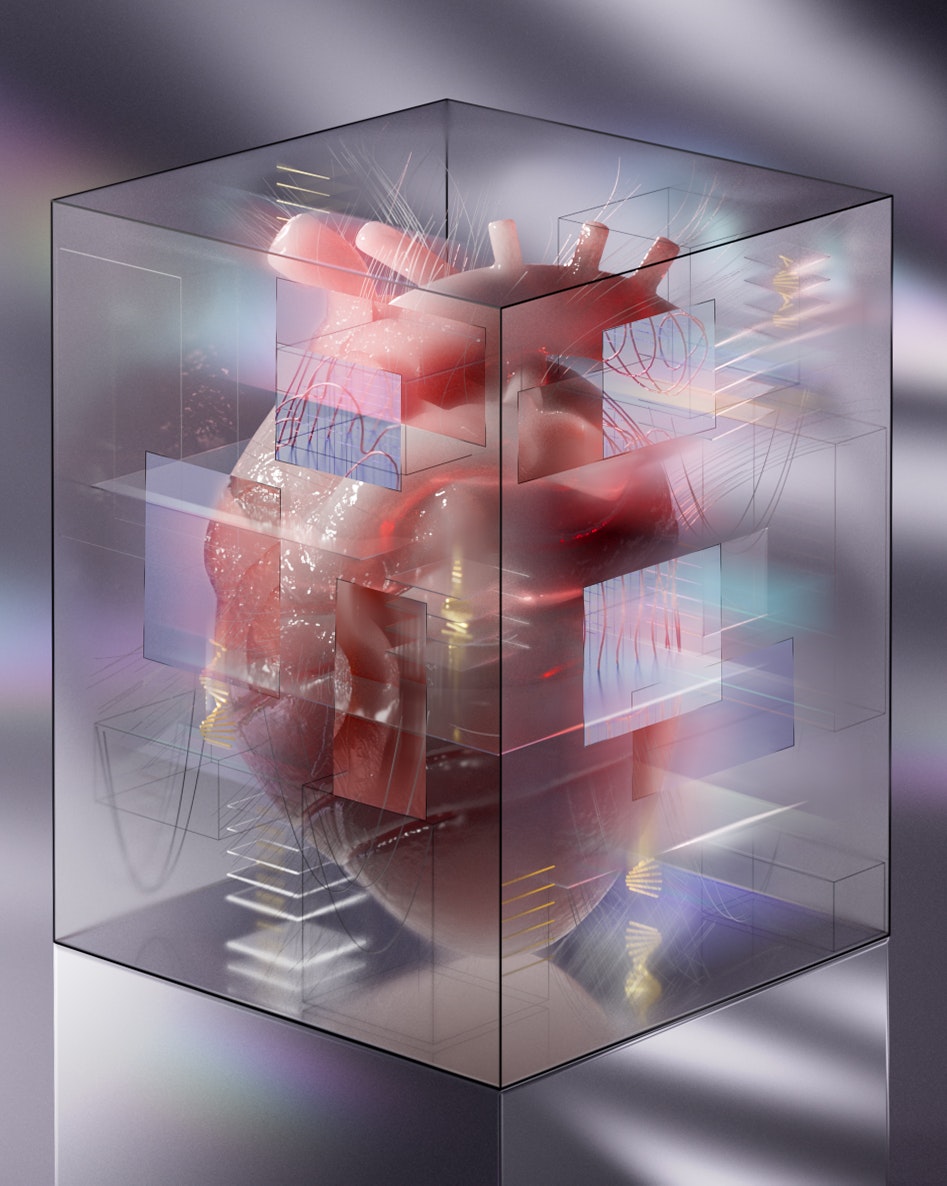

In today’s rapidly evolving technological landscape, digital twins are emerging as a groundbreaking innovation transforming project simulations across various industries. Digital twins, virtual replicas of physical entities or systems, leverage real-time data and advanced analytics to provide an accurate, dynamic model for simulation, analysis, and optimization. Their integration into project simulations marks a significant advancement, enabling project managers to predict outcomes more accurately, optimize processes, and mitigate risks effectively.

Understanding Digital Twins

Digital twins are sophisticated tools that create a virtual representation of physical assets. This process involves the use of sensors, IoT devices, and advanced software to collect real-time data, which is then used to construct a digital counterpart of the physical entity. The digital twin continues to evolve alongside its physical counterpart, updating continuously with new data, which allows it to simulate performance, predict failures, and improve efficiency.

The Role of Digital Twins in Project Simulations

The incorporation of digital twins into project simulations brings several advantages. By providing a comprehensive model that reflects real-world conditions, they enable project managers to test various scenarios without disrupting the actual project. This capability is particularly beneficial in complex projects where small changes can lead to significant impacts. Through digital twins, potential issues can be spotted and addressed in the virtual environment before they become real-world problems.

Enhancing Project Management Principles

One noteworthy aspect of digital twins is how they enhance the application of Project Management Principles. Principles such as risk management, scope management, and quality control become more robust with the insight provided by digital twins. For instance, risk management can be vastly improved through the predictive capabilities of digital twins, allowing managers to foresee and mitigate risks before they occur.

Case Studies: Digital Twins in Action

To illustrate the transformative power of digital twins, consider the following examples across different industries.

Construction and Infrastructure

In construction and infrastructure projects, digital twins have revolutionized the way simulations are conducted. By creating an accurate virtual model of a building or infrastructure, stakeholders can simulate different construction scenarios, optimize resource allocation, and enhance collaboration. This approach reduces the likelihood of errors, minimizes costs, and ensures projects stay on schedule.

Aerospace and Defense

The aerospace and defense industry has also seen significant benefits from digital twins. For example, aircraft manufacturers use digital twins to simulate the performance of their designs under various conditions. This capability allows them to identify and resolve potential issues before the aircraft is built, ensuring higher safety and performance standards.

The Impact on Project Management Education

The Australian Institute of Project Management (AIPM) recognizes the importance of incorporating digital twins into project management education. Offering cutting-edge courses and certifications, AIPM ensures that future project managers are well-versed in the latest technological advancements. By integrating digital twins into their curriculum, they provide students with invaluable experience in using this technology to enhance project outcomes.

Application in Renewable Energy Projects

Renewable energy projects, such as wind farms and solar plants, are another domain where digital twins are proving invaluable. These projects often involve large-scale installations in remote or difficult-to-access locations. By using digital twins, project managers can simulate the performance of renewable energy systems, optimize maintenance schedules, and improve the overall efficiency of energy production.

Benefits for the Automotive Industry

The automotive industry has been quick to adopt digital twins to enhance their production processes and product development. Digital twins allow automotive manufacturers to simulate the entire lifecycle of a vehicle, from design and production to maintenance and end-of-life recycling. This holistic approach ensures higher quality, cost efficiency, and a more sustainable production process.

Realizing the Full Potential of Digital Twins

As the capabilities of digital twins continue to expand, their potential applications in project simulations are virtually limitless. By integrating technology and real-time data, digital twins offer unparalleled insights that drive innovation and efficiency. The ability to test and refine projects in a virtual environment ensures better outcomes and maximizes the return on investment.

Importance of Continuous Learning and Adaptation

In conclusion, the integration of digital twins into project simulations is a game-changer for project management. By providing a dynamic, data-driven model, digital twins enable more accurate simulations, better risk management, and improved project outcomes. Project Management Principles must be applied as project managers continue to learn and adapt to these technological advancements to stay competitive in an ever-changing landscape. The Australian Institute of Project Management stands at the forefront of this educational evolution, offering resources and training to equip project managers with the skills they need to harness the power of digital twins. By embracing continuous learning and leveraging technologies like digital twins, project managers can lead their projects to new heights of success and innovation.

FAQs

What is a digital twin?

A digital twin is a virtual model of a physical asset, system, or process. It uses real-time data and advanced simulation techniques to replicate the behaviour, conditions, and performance of its real-world counterpart. Digital twins can help predict outcomes, optimize operations, and improve efficiency.

How do digital twins benefit project management?

Digital twins provide valuable insights by simulating various scenarios and identifying potential issues before they occur in the real world. This enhances risk management, quality control, and resource allocation, leading to more streamlined and successful project outcomes.

Which industries are using digital twins?

Digital twins are being utilized across a range of industries, including construction, aerospace, defense, automotive, and renewable energy. These industries benefit from the predictive and optimization capabilities of digital twins to ensure better performance, safety, and efficiency.

How are digital twins integrated into project simulations?

Digital twins are integrated into project simulations by creating accurate virtual models that reflect real-world conditions. These models are continuously updated with real-time data, allowing project managers to test different scenarios, predict performance, and implement improvements without disrupting the actual project.

What role does the Australian Institute of Project Management (AIPM) play in digital twin education?

The Australian Institute of Project Management (AIPM) offers cutting-edge courses and certifications that incorporate the latest technological advancements, including digital twins. This ensures that future project managers are well-versed in using digital twins to enhance project outcomes and drive innovation.

What are some challenges of implementing digital twins?

While digital twins offer numerous benefits, their implementation can be challenging due to the need for high-quality data, advanced analytical tools, and integration with existing systems. Additionally, there may be significant upfront costs and the necessity for ongoing maintenance and updates to ensure accuracy and effectiveness.

How can project managers stay updated with the latest advancements in digital twin technology?

Project managers can stay updated by engaging in continuous learning, attending industry conferences, and participating in advanced training and certification programs, such as those offered by the Australian Institute of Project Management (AIPM). Staying informed about the latest trends and technologies in digital twin development will help them remain competitive and effective in their roles.

What is the future outlook for digital twin technology?

The future outlook for digital twin technology is highly promising, with continuous advancements expected in data analytics, artificial intelligence, and IoT integration. These advancements will further enhance the capabilities of digital twins, making them even more valuable for optimizing processes, predicting outcomes, and improving project management across various industries.

Read another article ”Competitive Test-taking Strategies for Exam Acing EDUCATION”